Service

Home // Service

Sourcing..

- Madry Jeans merchandiser bares the responsibility of sourcing

- Madry Jeans have special sourcing team coordinates merchandiser to source the fabric, trims, laundry etc.

- The approvals related to fabric i.e. lab-dips, desk-loom, print-strike-off, dye-lot, thread run, needs to get from partner customers within time frame.

- The art work, trim card need to get approved from buyer which is responsibility of sourcing team under merchandiser.

- To maintain the proper buffer in Time and action calendar is the part of responsibility.

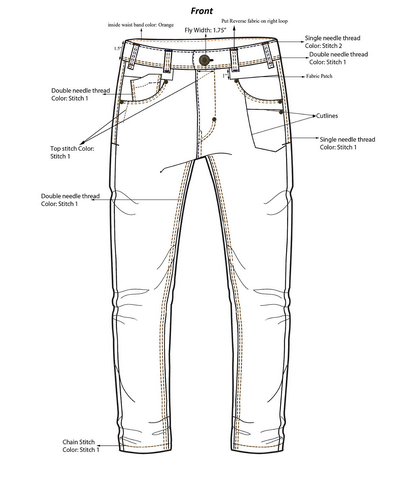

Design & Development

Madry Jeans Limited have dedicated design and developments team. Before going to bulk production, understanding the workmanship of any given new style is very important. If there any problem arises in early stage of development, it can be solved. Pricing or any kind of technical issue also.

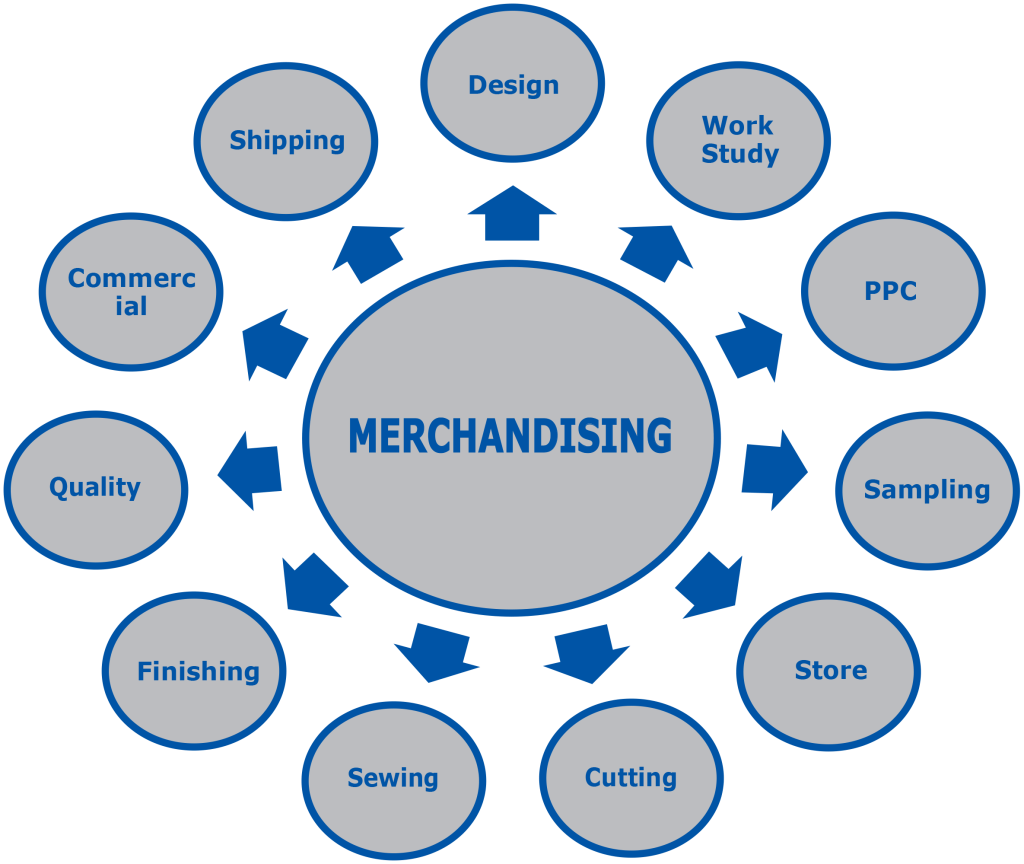

Merchandising..

Merchandiser is the BRIDGE between the industry and the buyer. He have to look after every job like buying the raw material which is required to finish the product, making the garment, finishing the garment, documentation, finally shipping. He is the responsible person to make the product. A garment export unit generally has many department like stores, cutting, production, packing, checking etc. in which Merchandising department a linking device of all. The job of a merchandiser is to co ordinate with the entire department in the office as well as the customers. The merchandiser is the one who creates a good relationship in between exporter and buyer.

Madry Jeans Limited have dedicated Merchandising team against each partner brands. They make sure bellow responsibilities …

- Internal and external communication,

- Sampling,

- Lab dips approval from customer

- Accessories and trims developments and getting approvals,

- Preparing internal papers for smooth executions,

- Advising and assisting production team avoid mistakes,

- Advising quality department about quality level,

- Mediating production and quality departments,

- Giving shipping instructions and following shipping,

- Helping documentation department,

- Taking responsibility for inspections and

- Following shipment.

Quality Control

Madry Jeans Limited are very much aware about the global RMG Business. The Managements are involve this sector since 2007 . Organizations worldwide have been exploring ways to improve business practices to gain competitive edge. An increasing number of organizations in developing countries are practicing Quality Management in order to generate improvements in performance and remain competitive.

The Madry Jeans Quality Team have a vision which the firm can only achieve through long-term planning, by drawing up and implementing annual quality plans which gradually lead the firm towards the fulfilment of the vision as well as integrated organizational effort designed to improve quality at every level. To be defined as a set of techniques and procedures used to reduce or eliminate variation from a production process or service-delivery system in order to improve efficiency, reliability, and quality. The QA team is an integrative philosophy of management for the continuous improvement of product and process quality in order to achieve customer satisfaction. Total quality management is a business approach aiming at providing quality products to achieve customer satisfaction. To approach business that attempts to maximize the competitiveness of an organization through the continual improvement of the quality of its products, services, people, processes, and environments. The idea is that the quality of products and processes is the responsibility of everyone who is involved with the development and/or use of the products or services. QA team involves management, workforce, suppliers, and even customers, in order to meet or exceed customer expectations.

Madry Jeans Limited have dedicated QA Officer to each Partner Factory to make sure quality , product service according to the customer requirements.

Views Today : 2

Views Today : 2 Views Last 7 days : 104

Views Last 7 days : 104 Views Last 30 days : 928

Views Last 30 days : 928 Views This Year : 3733

Views This Year : 3733 Total views : 25596

Total views : 25596